Text: Monika Kelle, Wolf Group brand manager

Count minutes, not hours. Thanks to breakthroughs in chemical formulations, long curing times in construction are no longer an issue.

To keep up with the times, the construction industry is moving towards faster, safer and more environmentally friendly products. Although Wolf Group can meet all of these criteria, one of its focal points has been to expand its range of effective products. Over the past few years, the company has been investing significantly in the development of fast-curing products. An Enterprise Estonia grant has enabled the group to innovate, using new raw materials and thinking outside the box. Some of its formulations are unique, while others are similar to those already available on the market, but with improved performance and user-friendliness.

Increase the tempo

The benefits of fast-curing formulas influence the entire sector, as saving time and increasing productivity gives companies a competitive advantage. For example, if builders have to wait until the next day to remove excess cured foam from a joint, this pushes the overall deadline for the project further back. Labour costs are high, so the quicker workers get their job done, the more the end-user saves.

Foam adhesives take the lead

One of the success stories of Wolf Group has been the development of one-component ready-to-use polyurethane foam adhesives, which have taken a tremendous market share from cement-based adhesives. Its latest addition, fast-curing multipurpose adhesives for indoors and outdoors applications, set remarkably quicker than traditional adhesives without compromising on quality. While conventional adhesives can take hours or even days to fully cure, their fast-curing counterparts accomplish the same task in a fraction of the time –often within minutes!

Don’t hesitate – go colder!

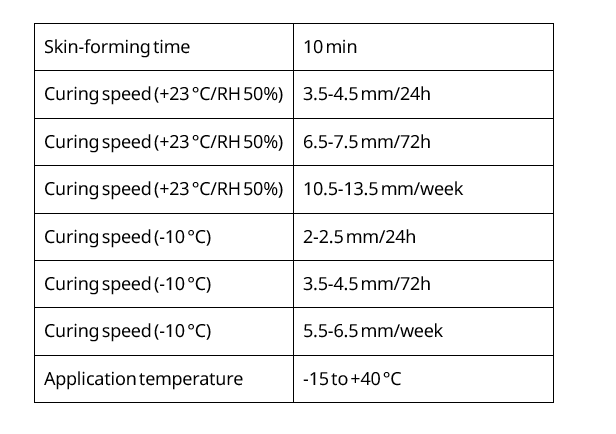

External factors, such as temperature and humidity, significantly influence the curing process and performance of building chemicals. Wolf Group has developed formulations that can withstand specific environmental conditions while achieving the optimal curing speed and strength. The latest addition to the portfolio is a fast-curing hybrid adhesive designed for use in cold climates and at low temperatures.

Practical aspects of application

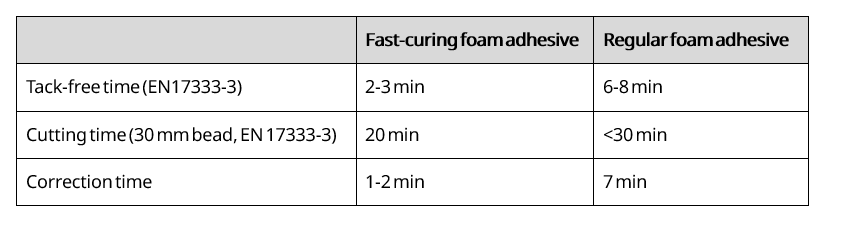

With all the benefits of fast-curing products, the question arises as to whether there is anything that needs to be considered. For example, if (foam) adhesives cure quickly, the correction time is usually shorter too. This means there is less time to make adjustments, particularly when installing boards.

Cleaning the foam gun more often is also essential, as the gun tip may be clogged or residual product inside the foam gun may have hardened.

Game-changers

Here are the Wolf Group’s TOP fast-curing products you won’t want to miss.

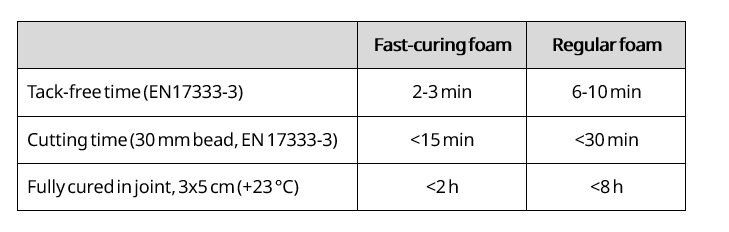

Fast Gun Foam. A one-component, fast-curing installation gun foam for various building applications, e.g. sealing of joints and penetrations, installation of window and door frames, and thermal and acoustic insulating. Its extra-quick curing time makes the building process faster. High yield allows you to do more work with one can. It adheres well to most materials like wood, concrete, stone, plaster, metal, PVC and polystyrene.

Fast Foam Adhesive. A one-component, ready-to-use polyurethane foam adhesive that cures quickly after dispensing. It is used for bonding different substrates in construction. It replaces the traditional cartridge adhesive, saves on application time and provides a strong bond. It is ideal for fixing insulation boards on facades and foundations, interior design boards, window sills and wooden, plaster and decorative panels.

MS Hybrid Adhesive Fast Curing & Cold Climate. A one-component, extremely fast-curing hybrid adhesive with exceptional performance, even in low temperatures. It was designed for demanding applications, both indoors and outdoors, where extremely fast curing is required. Maintains its elasticity while forming a durable bond and is perfect for the quick bonding of materials such as wood, concrete, metal and glass. It can be used in temperatures as low as -15 °C. Resistant to atmospheric agents: weather, extreme temperatures, ozone, UV ray exposure, overnight condensation, rain and more. It is meant for assembling components on manufacturing lines where fast handling and minimal downtime are needed. It can also be used for bonding lightweight structures in the production of appliances, HVAC systems and furniture, and boasts high-performance properties for mounting fixtures or equipment in refrigerated or cold-storage facilities.