Text: Veigo Kallaste, Industrial Sales Director

Images: Wolf Group

As an international manufacturer of construction materials, Wolf Group is increasingly focusing its product development efforts on comprehensive solutions. We have developed sealing and bonding solutions specifically designed for factory production of modular houses, concrete elements, ventilation equipment, and fenestration.

These days, a significant part of the construction process has shifted to factories due to clear advantages in efficiency, cost-effectiveness, and speed. Compared to on-site construction, factory production provides more favourable conditions: a controlled environment protected from weather effects ensures high quality, while standardised and automated processes reduce production waste and the ecological footprint.

Factories produce glass façade and precast concrete elements, modular and prefab housing units, ventilation equipment and systems, as well as windows and doors. Wolf Group supplies these sectors with various sealing materials – adhesives, construction foams, sealants, surface treatments, and more – both under its global brand Penosil and as private-label products. To make finding products easier, we’ve developed a web application where users can identify necessary products by application area directly from detailed technical drawings.

Solutions for modular houses

While the materials used in modular house construction are largely the same as those employed in on-site construction, additional expectations apply to products used in factories The curing speed of sealants, adhesives, and construction foams is significantly more important, as the time-factor is critical in the production process, and elements must be quickly moved or proceed immediately to the next stage of work on the production line. Product installation by machine is also becoming increasingly important to ensure maximum production efficiency. Once building modules are complete, they must be transportable to the construction site and installable without creating the need for additional work or repairs. Achieving this is often a major challenge, placing greater demands on the properties, compliance, and performance of the construction materials used. Equally important are the absence of unpleasant odours from raw materials and ensuring products are safe for health.

Wolf Group has developed specialised solutions and products specifically for modular housing manufacturers. Within our web application, clicking on a specific solution opens detailed views, enabling easy identification of appropriate products for each task, complete with technical information, documentation, and required certificates. Most of these products are listed in registries essential for modular housing export markets and hold the necessary low-emission certificates EC1 Plus and M1.

Going into detail

Next, we’ll focus on key construction joints and solutions. When joining panels, it’s advisable to explore Wolf Group’s wall and floor panel joint solutions, since building modules must be rigid, airtight, and fire-resistant. To effectively ensure these properties, adhesives and sealants should be used in combination with mechanical fasteners.

The construction of bathrooms and other rooms with higher than normal humidity levels requires special attention. The combination of moisture and warmth creates ideal living conditions for mould growth, and excess humidity can harm the building’s structures if not properly protected. Following our sanitary solutions helps prevent these issues.

Additionally, we offer specialised solutions and materials for modular house interior finishing works, flooring installation, fire protection works, and board gluing. Wolf Group also provides façade panels under our own Tempsi brand.

What to consider when installing windows?

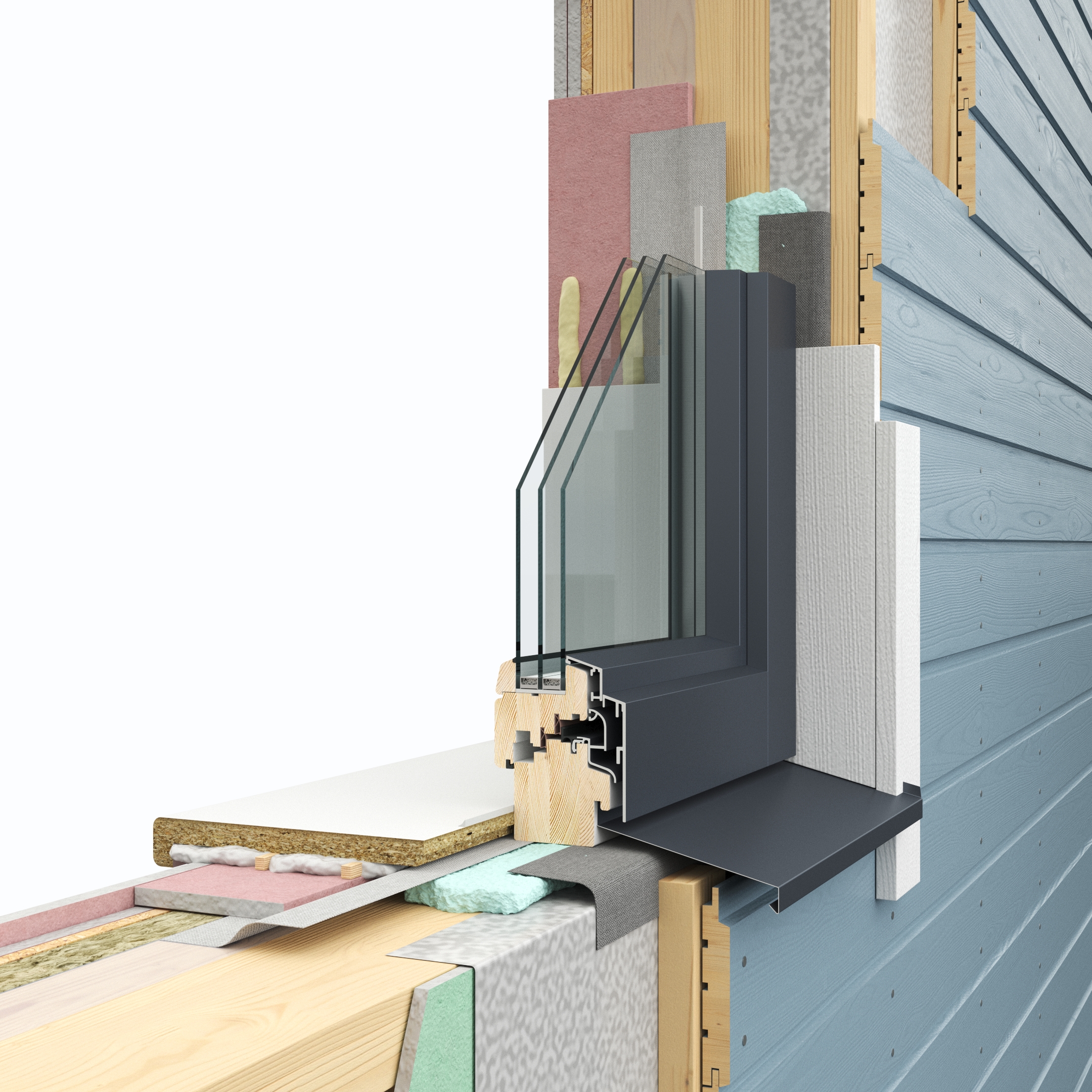

The window joint is considered one of the most complex and demanding aspects in construction. To minimise heat loss, the joints between the window frame and wall must be sealed with construction foam. For window installation, it is important to select foam that has an elastic structure and is able to accommodate the deformations of windows and structures, while also providing excellent thermal and sound insulation properties. To prevent heat loss, condensation, and mould formation, the joints between the window and wall should be sealed from the inside with air and vapour-proof tapes, and from the outside with wind barrier tapes. Foam adhesives can also be used for bonding various window reveal panels and window sills.

Wolf Group has extensive experience in sealing windows and doors as well as in energy saving. A significant portion of Penosil’s products is specifically designed for window sealing and finishing around windows.

Alongside installers, we have not forgotten window manufacturers. We offer glazing silicones as well as adhesives and sealants essential for window construction, weatherproofing, and ensuring air tightness. For more details, see our solutions for window and door manufacturing.

Manufacturing of ventilation equipment and accessories

To optimise the construction process, factories produce not only ventilation and cooling equipment, but also ventilation accessories, ducts, bends, and similar products. This ensures rapid and compliant on-site assembly of ventilation systems. Factory-controlled environments guarantee superior quality and efficiency. Due to increasingly strict air tightness and air quality requirements, different sealants have become indispensable. In addition to airtight products, we’ve developed sealants capable of withstanding short-term elevated temperatures during the powder coating process. Naturally, our products are also essential for the on-site installation of ventilation systems.

Prefabricated concrete elements

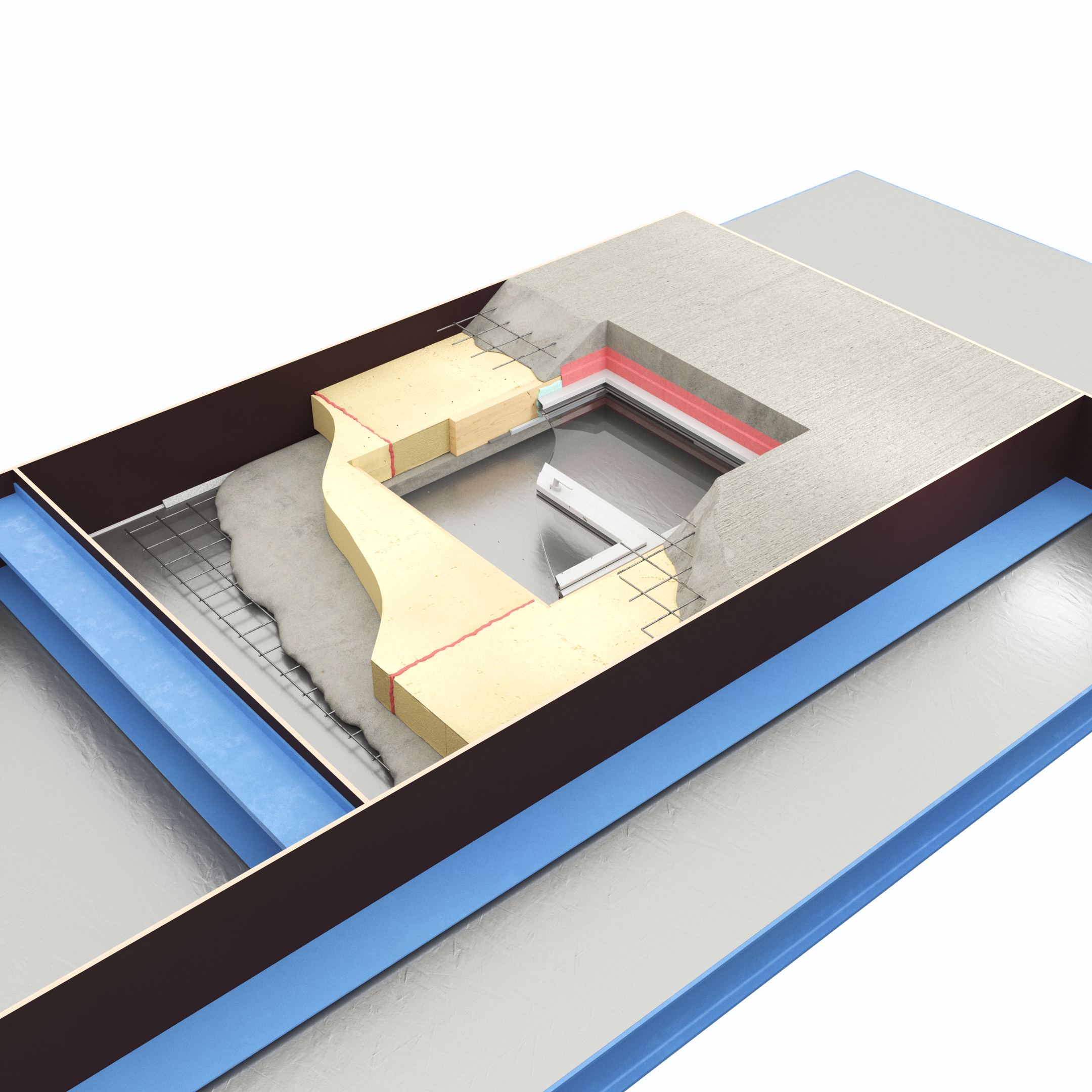

Factory-manufactured concrete elements significantly reduce construction time on-site while ensuring higher quality. We offer a variety of sealants and construction foams designed for sealing concrete casting moulds, preventing concrete leakage between formwork joints, as well as adhesives for attaching profiles and corners to the formwork. Our products provide strong adhesion, yet allow for easy cleaning of formwork panels afterward.

Insulation boards can be sealed using different types of construction foam. For filling narrower and deeper joints, Wolf Group has developed a patented applicator that fits onto the foam gun valve, featuring a slimmer tube diameter than the gun itself. Penosil’s product range includes a series of insulation and adhesive foams equipped with the EasyGun applicator. We have also developed a new solution for gun foams, where narrow brass barrel extensions designed specifically for filling narrow joints can be attached to foam guns.

Another growing trend in this sector is the factory installation of windows. For this purpose, we’ve developed a specialised installation solution and corresponding products tailored specifically for precast concrete elements.

Additionally, we offer an extensive range of products suitable for installation works, such as sealing façade joints. For this purpose, we’ve developed concrete façade sealing solutions.

Marko Kanarbik, Harmet OÜ

Harmet values partners and high-quality products that help ensure the excellence of our modular houses and the efficiency of our manufacturing processes. Collaboration with Wolf Group has strategically proven to be the right move. Their product development takes into account the unique requirements of factory production, and together we’ve developed products with optimal consistency and rapid curing. A valuable bonus has been Wolf Group’s professional technical support, quick responsiveness, flexibility, and attentive, customer-focused communication.

We’ve used Wolf Group’s Penosil-branded products for modular house manufacturing destined for both the Scandinavian market and reconstruction efforts in Ukraine. The product range utilised in our construction process has been extensive, from materials for window installation to various adhesives, sealants, and fire-protection products.

Madis Haasma, Wolf Group Industrial Sales Manager

The shift of construction into factories is a definite, lasting trend—not just a passing phase. Wolf Group is always present wherever our customers are, which is why we’ve made substantial investments in the factory construction sector in recent years. This industry is rapidly evolving, and alongside providing technical product support, we’ve launched a web application that helps manufacturers of modular houses, window and door systems, precast concrete elements, ventilation equipment, and more find suitable solutions and products quickly. As an internationally operating company, Wolf Group’s clients appreciate our willingness to share our experience and best practices from various markets. During these transformative times, it’s crucial for Estonian companies to stand together to ensure prosperity for our country and its people.